HVAC BIM services

HVAC BIM (Building Information Modeling) services refer to the use of digital technologies and processes to design, simulate, and manage the heating, ventilation, and air conditioning (HVAC) systems in construction projects. These services utilize 3D modeling software to create detailed, data-rich models of HVAC systems, which help improve the efficiency, performance, and collaboration across the lifecycle of a building. Here’s an overview of what HVAC BIM services typically involve:

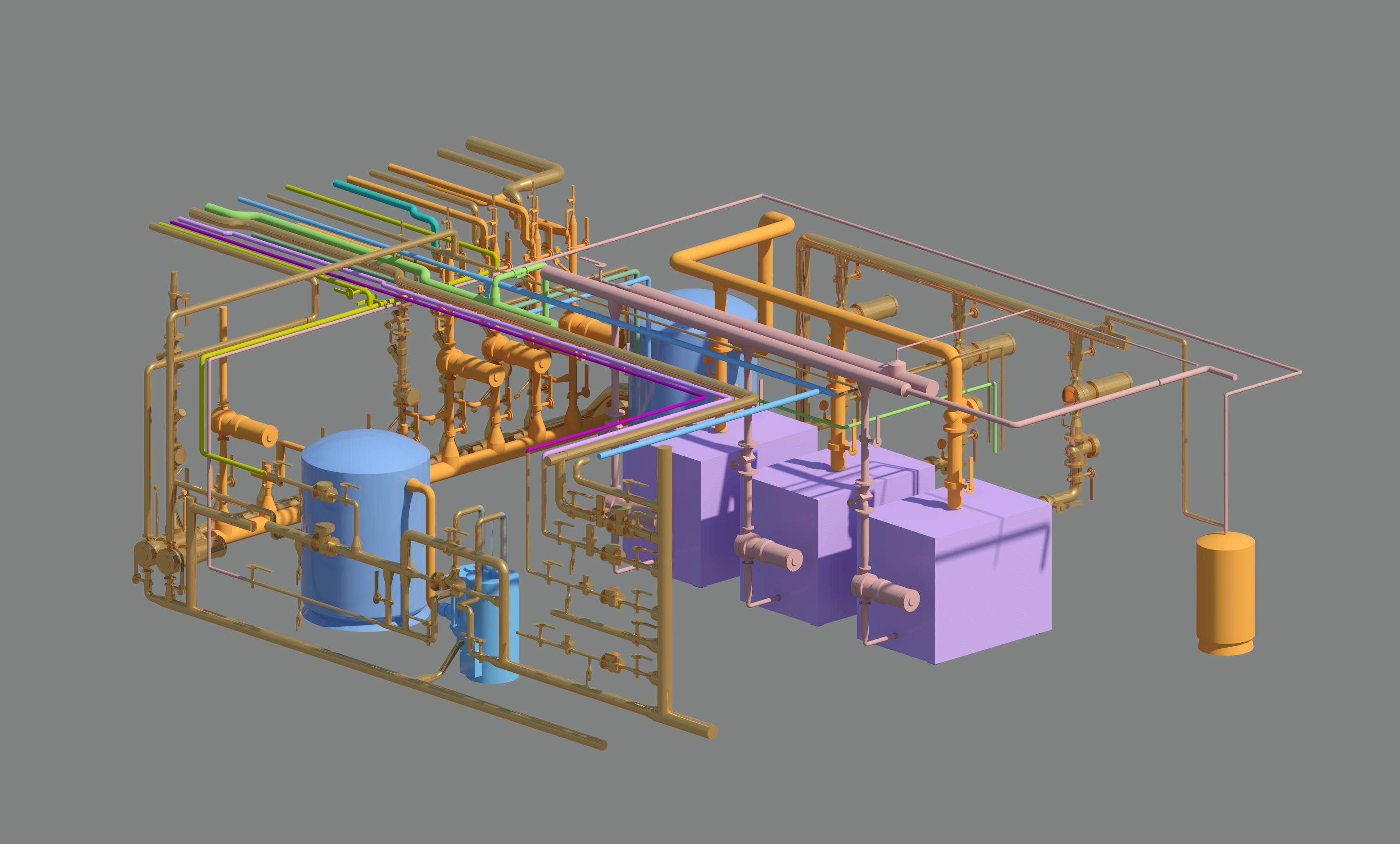

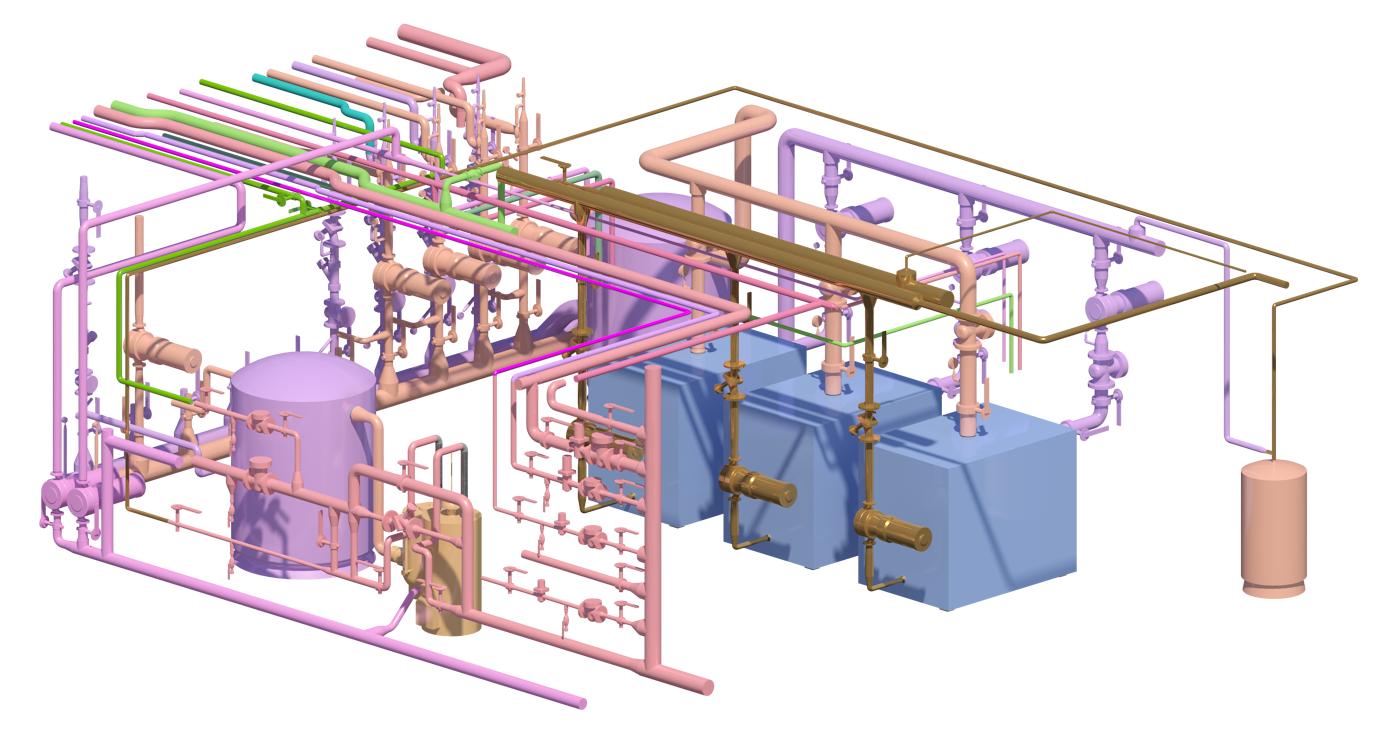

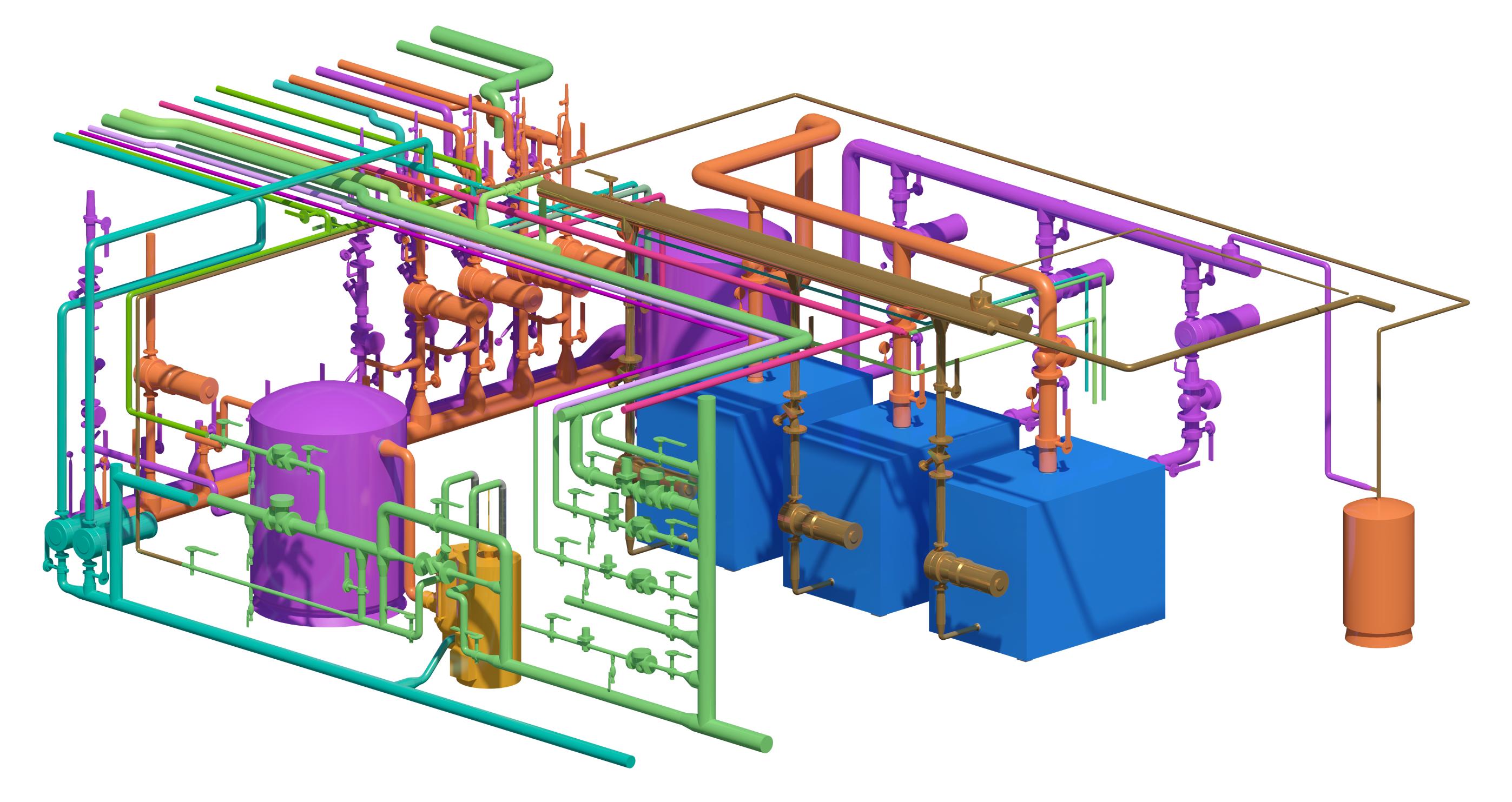

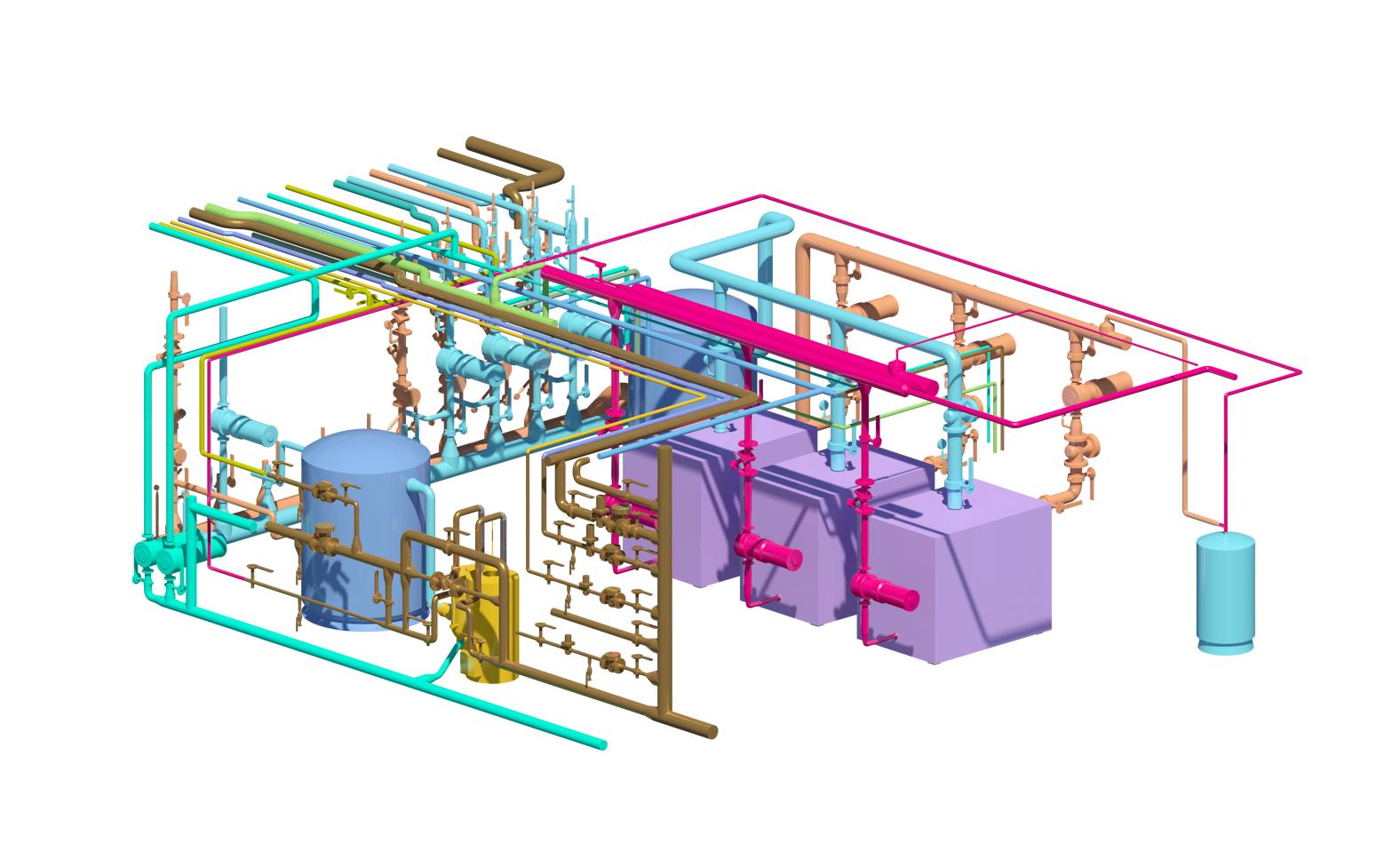

1. HVAC System Design & Modeling

3D Modeling: Creation of 3D models of HVAC systems to visualize the layout, ducts, pipes, equipment, and related components. This helps in identifying clashes early and optimizing space utilization.

Component Selection: Selection of the right components for the HVAC system, including air handling units (AHUs), ducts, ventilation fans, heating and cooling units, and control systems.

Load Calculations: Calculation of heating and cooling loads for the building to ensure that the HVAC system is appropriately sized.

Energy Modeling: Integration with energy modeling tools to simulate energy consumption and optimize the system for energy efficiency.

2. Clash Detection & Coordination

Clash Detection: Use of BIM to identify and resolve potential clashes between HVAC components and other building systems (electrical, plumbing, structural) before construction begins, reducing costly rework.

Interdisciplinary Coordination: Collaboration with other building disciplines (architecture, structural, electrical, plumbing) to ensure smooth integration of HVAC systems into the overall design.

Our team is also having knowledge in design and code aspects, so that while clash check they can change the duct size as per aspect ratio change route without going back and forth all the time with contractors.

3. Simulation & Performance Analysis

Thermal Comfort Analysis: Evaluating the HVAC system's ability to provide comfort within indoor spaces, ensuring proper air distribution and temperature regulation.

Ventilation Analysis: Simulating airflow patterns to ensure effective ventilation, including the distribution of fresh air and removal of pollutants.

Energy Performance: Analyzing the efficiency of HVAC systems in terms of energy consumption and identifying opportunities for optimization.

4. Construction Documentation

Detailed Drawings: Generating detailed, accurate construction drawings for the installation of HVAC systems.

Specifications & Schedules: Creating material specifications, equipment schedules, and installation guidelines for contractors.

5. Prefabrication and Modularization

Prefabrication Models: BIM can be used to create prefabricated HVAC components, which are built off-site in controlled environments, improving quality and reducing construction time on-site..

Modular Systems: Designing HVAC systems with modular components that can be assembled more efficiently on-site.

6. HVAC System Installation and Construction Management

Installation Guidance: Providing detailed installation instructions to ensure that HVAC systems are installed correctly according to the design model.

Project Management Support: Assisting in project scheduling, budgeting, and progress tracking through BIM, helping to avoid delays and cost overruns during the construction phase.

7. Maintenance & Facility Management

As-Built Models: Creating as-built models that document the final installation of HVAC systems, which are useful for ongoing maintenance and facility management.

Operation & Maintenance (O&M) Manuals: Providing digital O&M manuals with access to information about HVAC components, maintenance schedules, and troubleshooting.

Lifecycle Management: Managing the lifecycle of HVAC systems, including service schedules, upgrades, and end-of-life planning.